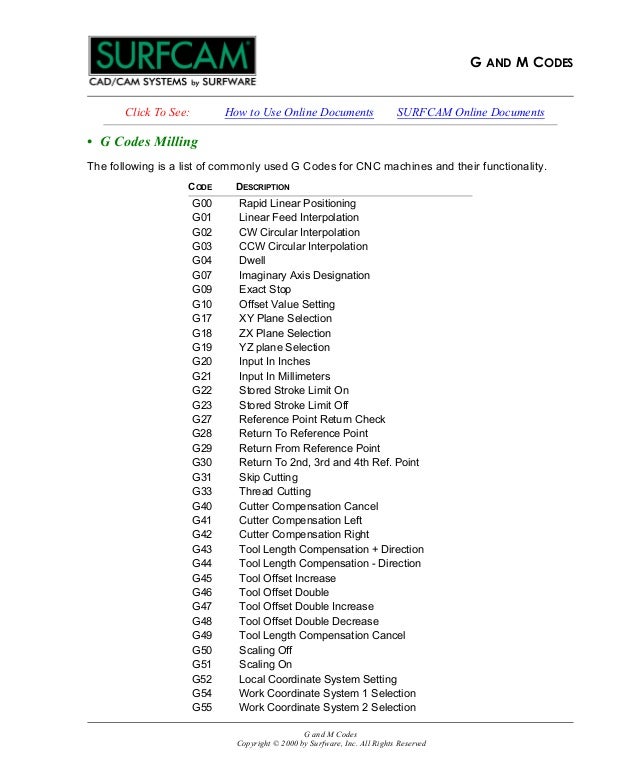

G & M Code Tables for Milling

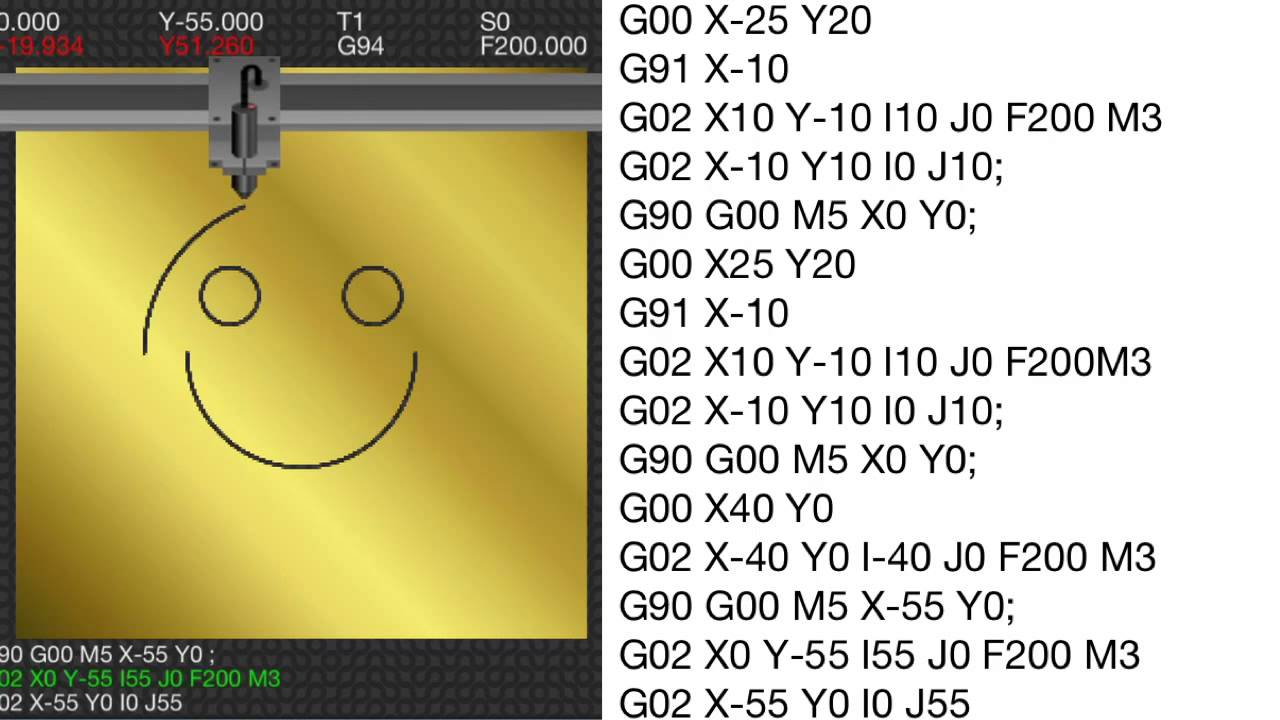

A list of common G- and M-codes for reference. Feed rate Tool length G-code Tap & clearance Settings G- & M-code Charts. search codes. G-codes; code description; G00: Rapid repositioning: G01: Linear interpolation: G02: Clockwise circular/helical interpolation: G03: Counterclockwise circular/helical interpolation.

How to a GCode master with a complete list of GCodes Robotics & Automation News

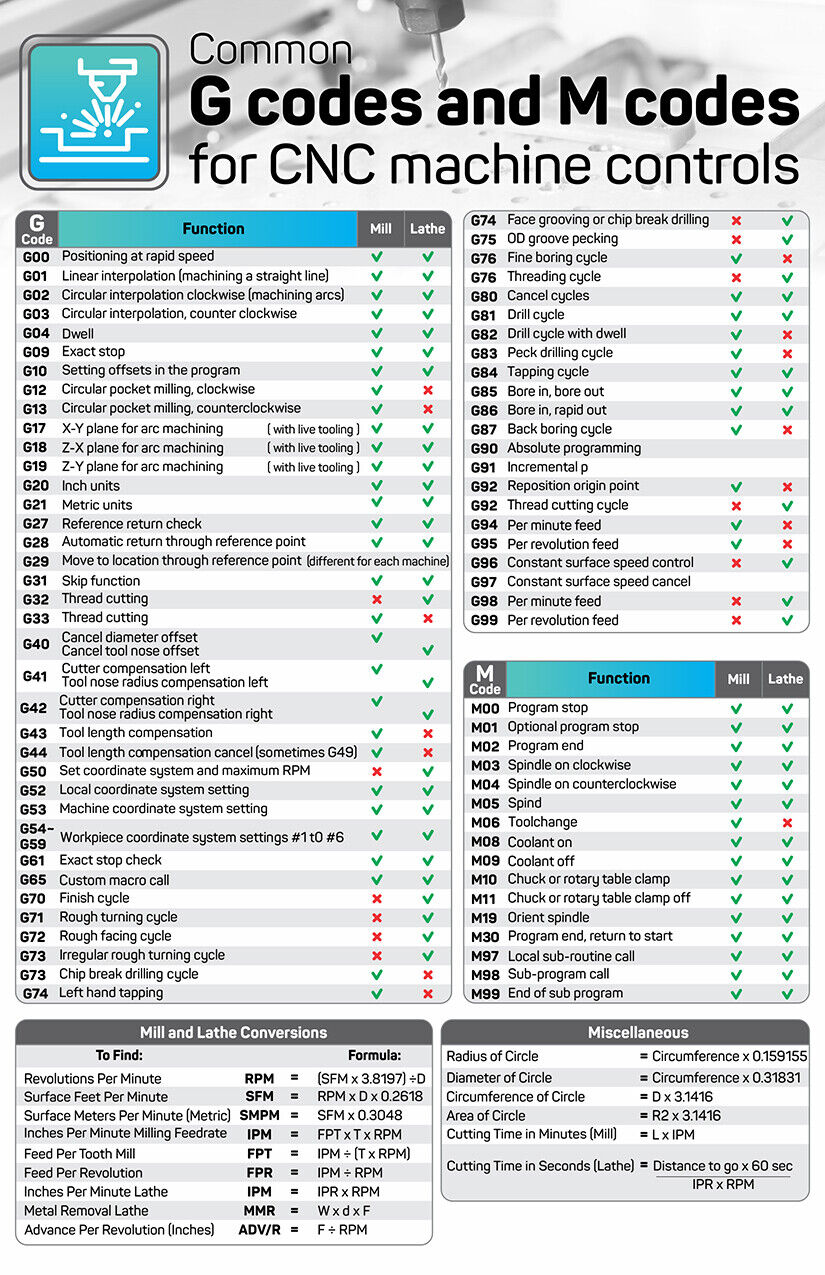

G-code activates the CNC machine, and M-code activates the machine's programmable logic controller. G-code commands often differ in CNC machines, while most M-code commands remain the same. CNC machines have transformed the manufacturing industry and simplified the process of producing precise and consistent parts.

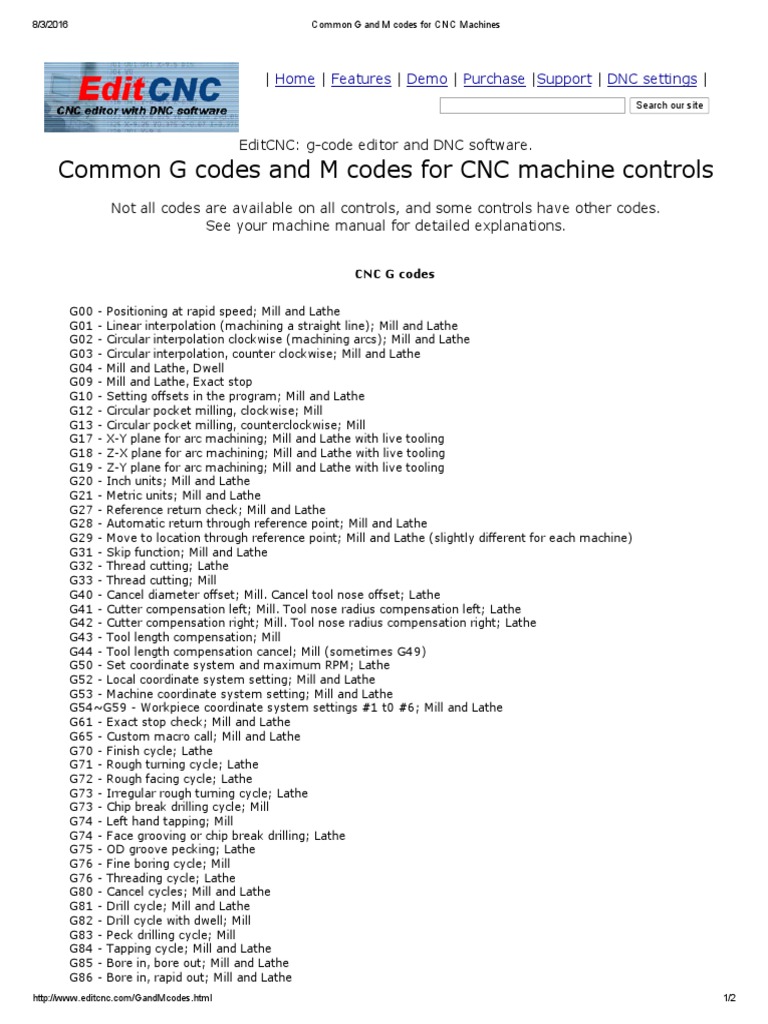

Editcnc Common G Codes And M Codes For Cnc Machine Controls Drilling Industrial Equipment

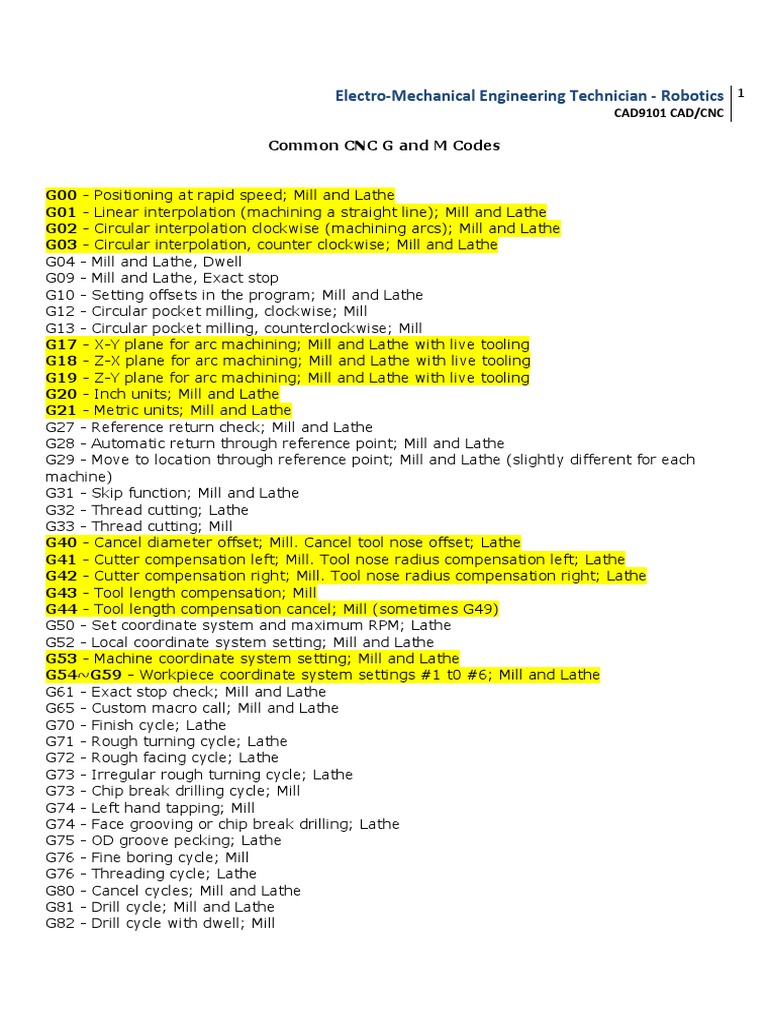

We listed 70 G codes in our list alone but in reality there are many more. Some will have different meanings on lathes vs mills. Also, different CNC controller manufacturers will include their own special codes. For example, some will have codes such as G103 or they will switch the meaning of a code. You should always know how your individual.

GCode and MCode List for CNC [ Easy To Use, Examples & Tutorials ]

G-codes Used on CNC Mills. The following is a list of G-codes used to program CNC mills and machining centers. G code. Function. G00. Rapid positioning. G01. Linear interpolation. G02.

CNC Machining G Code and MCode

Unlike common perception, G codes and M codes hold distinct roles in CNC operations. G codes primarily instruct the machine on the geometry of the cut, while M codes control the hardware aspects, like turning the spindle on or off. This nuanced difference is pivotal for understanding the full potential of CNC machining.

Common CNC G and M Codes Drilling Numerical Control

G-codes command the machine's motion and function for the product's design, while M-codes are used to conduct the non-movement operations of the programming. G-code initiates the CNC machine while the M-code initiates the machine's programmable language controller (PLC).

Common G and M Codes for CNC Machines Drilling Industrial Equipment

M11 - Chuck or rotary table clamp off; Lathe and Mill. M19 - Orient spindle; Lathe and Mill. M30 - Program end, return to start; Lathe and Mill. M97 - Local sub-routine call; Lathe and Mill. M98 - Sub-program call; Lathe and Mill. M99 - End of sub program; Lathe and Mill. List of commonly used G and M codes for CNC machines.

G and m codes

M Code/G Code List. Below you will find a list of common codes many builders use. Please remember, all machines may be configured differently and the list below may not match your machine perfectly. If fact, virtually all M-Codes above M79 will vary from builder to builder. Please make sure to contact your machine tool builder to be sure.

Common G Codes and M Codes For CNC Machine Controls PDF Drilling Crafts

called (G00, G02, G03, etc.). All G codes not in group 0 behave this way. Only one M code can be specified in a single block. Same holds true for all other words. Generally leading zeroes are not required in G Code. For example G01 and G1 are the same. The same holds true for M codes, position commands, feed rates, etc.

Common G and M Codes For CNC Machines PDF

Summary of M-Codes All MachMotion CNC controls use the Mach3 or Mach4 software. Use the M-code list below as a reference. Download. Mach 3 G-Code Language Reference. Download. Mach 4 G- and M-Code Language Reference.

Introduction About G Code and M Code In CNC Manufacturing SANS

GCode Simulator. Fanuc Alarm Code List. Complete g code list with m-codes for milling in the Fanuc, LinuxCNC, GRBL, and Haas dialects. We give a quick definition for all g code commands along with a link to tutorials and examples of how to use it. Click the g-code link (if any) to visit a tutorial from our popuplar Online Free G-Code Training.

CNC G Codes Cnc, Cnc programming, Cnc codes

G AND M CODE. 6/30/15. R0135. This manual covers the G and M-codes used in Mach4 Lathe. Formatting Overview: Menus, options, icons, fields, and text boxes on the screen will be bold (e.g. the Help icon). Clickable buttons will be bold and within brackets (e.g. the [OK] button). Directory names, commands, and examples of editing program files.

G and MCodes In CNC Explained Difference, Usage And More.

G codes for CNC milling. The following are some of the commonly used G codes and their description in CNC milling. G00 - Rapid positioning. G01 - Linear travel/interpolation. G02 - Circular travel/interpolation (clockwise) G03 - Circular interpolation (Anti-clockwise) G04 - Dwell. G10 - Programmable data input.

Common GCodes & MCodes for CNC Machines Chart 5.5"x8.5" eBay

G-code, also known as "geometric code" or "preparatory code," is primarily used to define the motion and positioning of the cutting tool. These codes instruct the machine on how to move, such as rapid motion (G00), linear interpolation (G01), and circular interpolation (G02 and G03), among others. On the other hand, M-code, also known.

Cnc Programming

G - M-Code List and Syntax: G-Codes do not require attributes unless stated G1 Linear Move: Ex: G1 Z1.2 ;Move the Z axis 1.2 in. in the positive direction The G1 command allows for all axes to move synchronously in a contoured linear motion. The parameters supplied will cause a motion in either a relative or absolute

G Code Alias M Code Alias (How to use them) CNC Training Centre

A more complete list of G- and M-Codes. For those interested, here is a more complete list of common codes. G00 Rapid move G0 X# Y# Z# up to eight axes or G0 Z# X#. G01 Feed Rate move G1 X# Y# Z# up to eight axes or G1 Z# X#. G02 Clockwise move. G03 Counter Clockwise move.

- Silver Hair Colour For Men

- James Stewart Sarah Roberts Split 2023

- Bob Jane T Marts Macgregor

- Panasonic Dvd Remote Control Replacement

- فیلم سینمایی جدید بدون سانسور آمریکایی

- Dumas Alexandre The Three Musketeers

- Cathedral Invitational Prize Money Breakdown

- Bourke St Mall Melbourne Shops

- Infidel Book Ayaan Hirsi Ali

- Little Red Riding Hood Red Cape