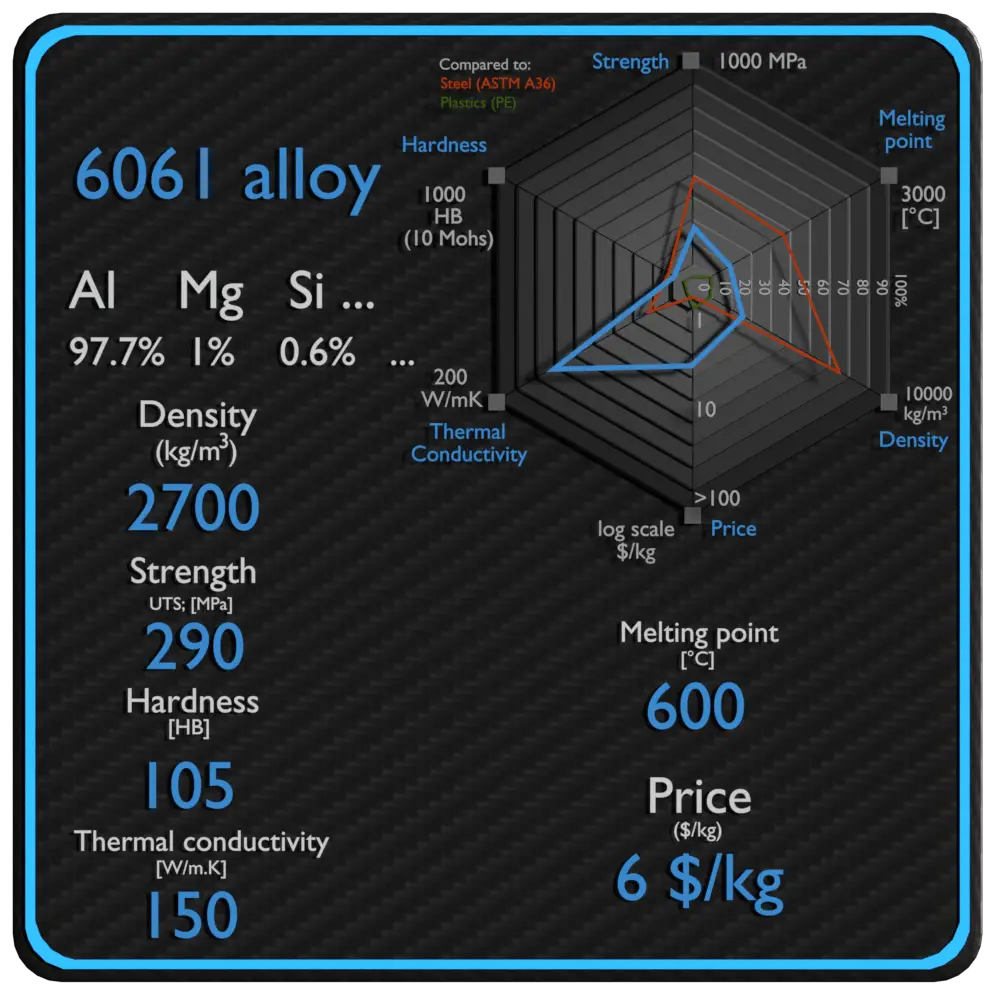

Aleación 6061 Densidad, resistencia, dureza, punto de fusión

6061-T6 Aluminum. 6061-T6 aluminum is 6061 aluminum in the T6 temper. To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 6061-T6 aluminum to: 6000-series alloys (top), all aluminum alloys (middle.

What is 6061t6 Aluminum?

Aluminium 6061-T6 is a subcategory of the 6061 aluminium alloy, one of the most widely used aluminium alloy categories in the world. The alloy is appreciated because of its versatile performance and all-around mechanical properties. The "T6" part of the 6061-T6 name indicates the type of tempering treatment process that this aluminium alloy.

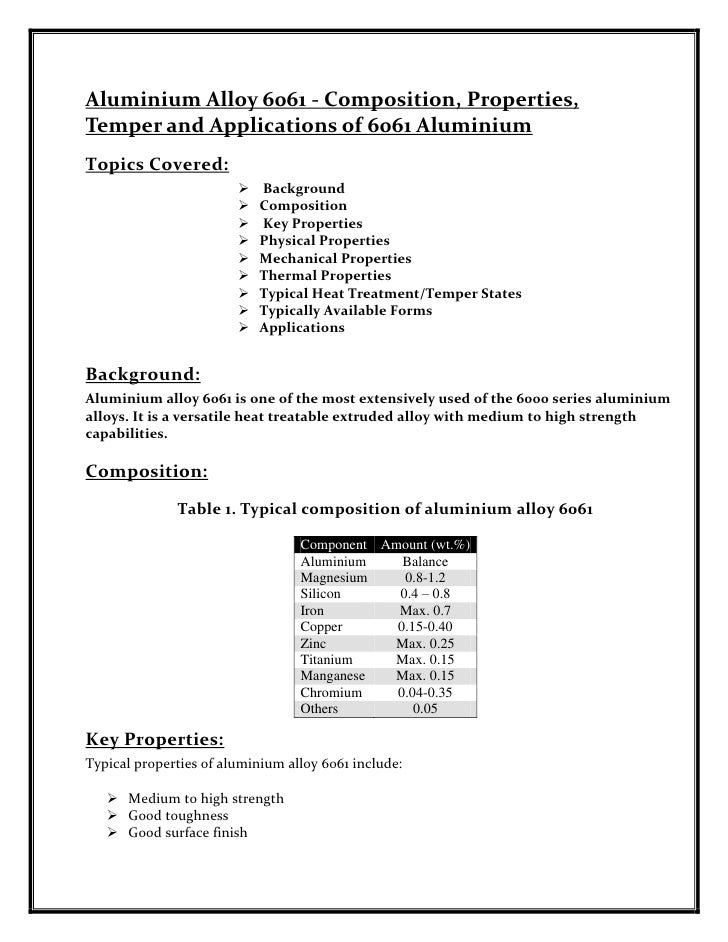

Aluminium alloy 6061

Aluminum 6061 -T6; 6061 -T651 Categories: Metal ; Nonferrous Metal ; Aluminum Alloy ; 6000 Series Aluminum Alloy Material Notes: Information provided by Alcoa, Starmet and the references. General 6061 characteristics and uses: Excellent joining characteristics, good acceptance of. Component Elements Properties Metric English Comments.

Metals Free FullText Research on LaserTIG Hybrid Welding of 6061T6 Aluminum Alloys Joint

6061-T6 aluminum properties include its structural strength and toughness. It is also offers good finishing characteristics and responds well to anodizing, including clear, clear and color dye, and hardcoat. 6061 aluminum alloy is also easily welded and joined. However, in its -T6 condition the welds may lose some strength, which can be.

Aluminum 6061 T6 Aluminum 6063 aluminum roofing sheet

Essential Aluminum 6061 Material Properties.. 45 ksi for 6061-T6). Though the tensile strength of 6061 is half that of 7075, it is still strong enough for many constructional applications. Compressive Strength. The ultimate compressive strength of aluminum 6061 changes with different composite materials. For example, by increasing the weight.

The Properties of 6061 Aircraft Aluminum

Aluminum 6061-T6; 6061-T651. Categories: Metal; Nonferrous Metal; Aluminum Alloy; 6000 Series Aluminum Alloy. Material Notes: General 6061 characteristics and uses: Excellent joining characteristics, good acceptance of applied coatings. Combines relatively high strength, good workability, and high resistance to corrosion; widely available.

6061T6 Aluminium The Ultimate Guide EngineeringClicks

6061 Aluminum Alloy (Al 6061-T6, 6061-T651, 6061-T4) Al-6061 aluminum alloy is a general purpose structural alloy developed by Alcoa in 1935. The temper designations mainly have 6061-T4, T451, Al 6061-T6, 6061-T651, etc. It is one of the most widely used alloys. The main alloying elements are magnesium (Mg) and silicon (Si).

Aluminum 6061T6 rear wall material properties Download Table

Linear Expansion of AL 6061-T6 from 0K to 300K. Thermal Properties Database for Materials at Cryogenic Temperatures. Ed. Holly M. Veres. Volume 1 Recommended values of the Thermophysical Properties of eight Alloys, Major Constituents and their Oxides Y.S.Touloukian ( Purdue University) Feb, 1965

6061T6 Aluminum IBeam with AMSQQA 200 standard for construction structure

Thermal Properties of 6061 Aluminum. Here we can see some thermal properties of the alloy including the coefficient of thermal expansion and thermal conductivity. Both the T4 and T6 tempers are included. Property. 6061-T4. 6061-T6. Coefficient of Thermal Expansion @ 20.0 - 100 °C Temp. 23.6 µm/m-°C | 13.1 µin/in-°F. 23.6 µm/m-°C | 13.1.

Sunrise Steel Centre Aluminium 6061 T6 Round Bars, Aluminium 6061 T6 Black Bars, UNS A96061

Aluminium alloy 6061 is a medium to high strength heat-treatable alloy with a strength higher than 6005A. It has very good corrosion resistance and very good weldability although reduced strength in the weld zone. It has medium fatigue strength. It has good cold formability in the temper T4, but limited formability in T6 temper.

84 6061 STEEL MATERIAL PROPERTIES * Materials

Aluminum Alloy 6061 (UNS A96061) Aluminium 6061 is a heat-treatable wrought alloy composed mainly of magnesium, silicon, and aluminium. It is characterized by good strength, corrosion resistance, weldability, and machinability. The following table provides a list of aluminum 6061 properties in both SI and US customary/Imperial units.

6061 Aluminum Properties EngineeringClicks

The mechanical properties of 6061 aluminum alloy differ based on how it is heat treated, or made stronger using the tempering process. To simplify this article, the strength values for this alloy will be taken from T6 tempered 6061 aluminum alloy (6061-T6), which is a common temper for aluminum plate and bar stock. Its modulus of elasticity is.

PPT 6061 T6 Aluminum PowerPoint Presentation, free download ID5059986

Overview. Aluminum 6061-T6 is the one of the most common types of aluminum metals used in the industrial world today. With its high strength-to-weight ratio and excellent machinability, it is perfect for applications in aerospace, transportation equipment and construction materials manufacturing. Aluminum 6061-T6 is generally heat treated and.

Material properties of 6061T6 Aluminum alloy. Download Table

6061 Aluminum Alloy: Properties General Characteristics Characteristic Appraisal Strength Medium to High Corrosion Resistance Good. Thermal Properties Property 6061-T4 6061-T6 Coefficient of Thermal Expansion @ 20.0 - 100 °C Temp 23.6 µm/m-°C | 13.1 µin/in-°F 23.6 µm/m-°C | 13.1

fatigue design curves for 6061 t6 aluminum basicstagemakeuptutorial

A summary of the materials property information for aluminum alloy 6061 is presented. The scope of the information includes physical and mechanical properties of the alloy at cryogenic, ambient, and elevated temperatures. Information on material procurement, metallurgy, corrosion, environmental effects, fabrication, and joining techniques is developed.

Jindal Aluminum Aluminium Flat 6061 T6, Thickness 1 mm To 250 mm at Rs 250/kg in Mumbai

6061-T6 aluminum alloy offers a unique combination of strength, corrosion resistance, and machinability, making it a go-to material for various industries. Its exceptional properties enable its use in aerospace, automotive, marine, and structural applications. Whether constructing aircraft, designing consumer electronics, or building marine.

- Smiley Gets A Gun 1958 Movie

- Kl International Airport To Kl Sentral

- How To Draw Minecraft Steve

- North Metropolitan Tafe Perth Building 1

- Khách Sạn Lotte Sài Gòn

- Who Has Played For West Coast And Sydney

- Another Word For Fast Learner

- Soundtrack To Gone In 60 Seconds Movie

- Accommodation Near Convention Centre Gold Coast

- The Last Ship Season 6